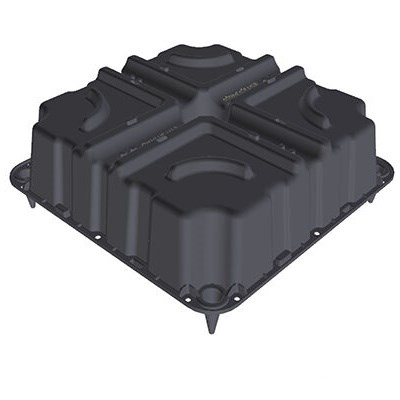

Volimax | Hollow Slab Blind Mold

Please click on "Offer Request" button below to send your offer and detailed information request to the company for the Volimax | Hollow Slab Blind Mold product.

Hollow slab is obtained by placing blind molds made of recycled polypropylene (PP) between the lower and upper reinforcement in such a way that the slab runs in both horizontal directions and pouring the concrete in place.

The products are placed at the intervals specified in the project and connected to the lower reinforcement. After the upper reinforcement is placed, concrete pouring begins. The most important point to be considered while pouring concrete is to pour the concrete in two times so that the products do not float, but not to allow the formation of cold joints between the two castings. In the first casting, the concrete is poured until it completely covers the edges of the blind molds. According to the class of the concrete and the weather conditions, when the concrete is slightly plasticized and reaches a consistency that will not allow fingers to enter, the second casting is performed and the flooring production is terminated. Vibrator should be used at every stage of concrete casting.

PP

• Width and length: 52×52 cm

• Height:

- Single use 10, 13, and 16 cm

- Double, triple and quadruple use 10, 13 and 16 cm combinations

• Center cone concrete observation hole

• 2 cm spacer integrated into the mold

• Conical leg heights varying between 7-12 cm

• Made from recycled polypropylene