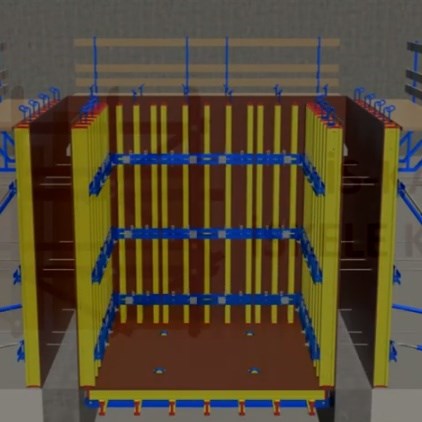

Industrial Wall and Column Formwork

Please click on "Offer Request" button below to send your offer and detailed information request to the company for the Industrial Wall and Column Formwork product.

Wooden Beam Formwork System is used as a curtain, circular curtain, single-sided curtain, column and adjustable column formwork in different structures such as industrial buildings, infrastructure constructions, high-rise buildings, bridge piers, residential constructions and retaining walls.

Safe and easy concrete pouring is provided with the working console. The system is designed by our company according to your mold projects. In our designs, fresh concrete pressure of 50 kN / m² in walls and 90 kN / m² in columns is taken into consideration. As the panel sizes increase, the mold circulation speed increases. Since the mold surface is wide and flat, a smooth concrete surface is obtained. It is possible to create special cross-section or circular column molds with reservation elements. Smooth and high quality surfaces are obtained with little workmanship.

It is economical, convenient and fast. Automatic gas welding machines are used in our production. The system is specially painted with anti-rust paint and can be coated with galvanize upon request. Wooden Beamed Formwork System is a flexible system that can be adapted to different projects and strengths. It is possible to solve different projects using the same parts. NPU100 U iron is used in steel belts.

All cast products are ductile iron. Welding is done with gas welding machines without burrs. The economic life of the products is at least 10 years.