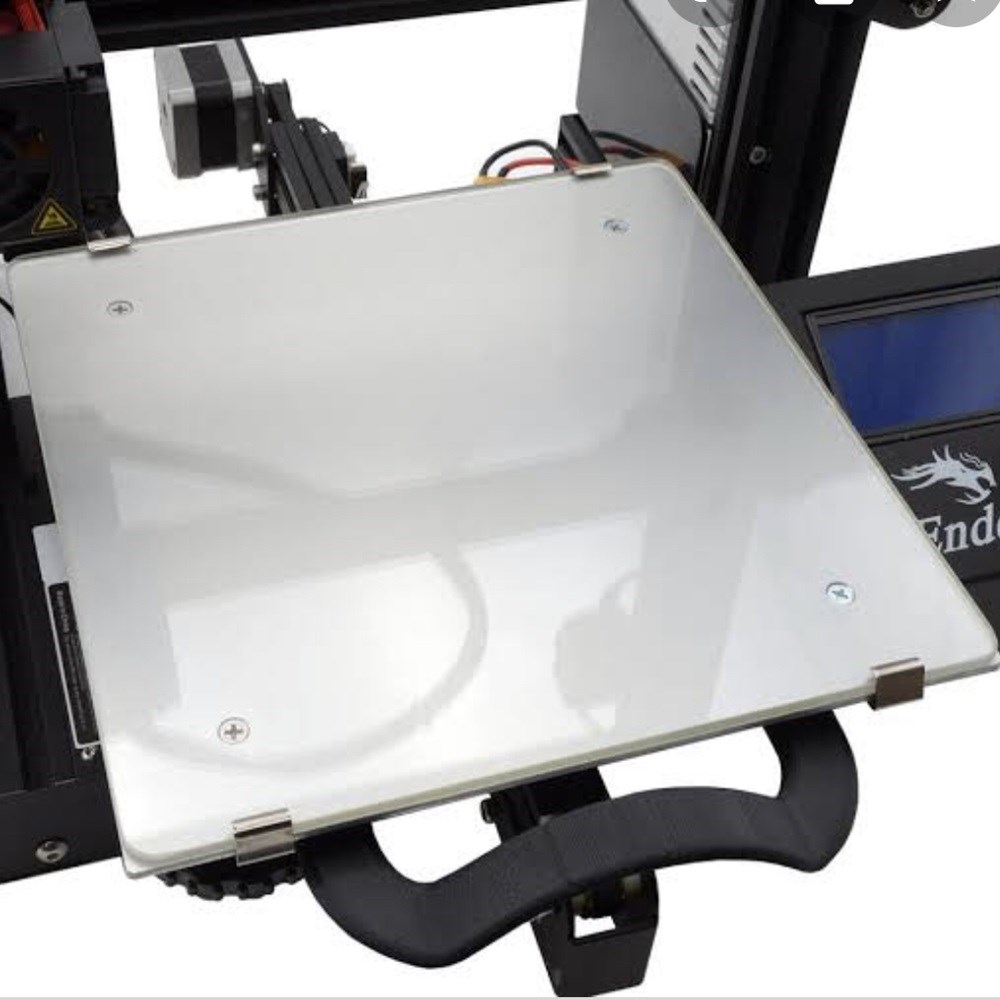

Borosilicate Glass - For 3D Printers

Please click on "Offer Request" button below to send your offer and detailed information request to the company for the Borosilicate Glass - For 3D Printers product.

3D printers

• Non-glass materials deform after each use. Printed trays such as plastic and aluminum are rarely completely flat, even when new. They continue to bend with heat or stress. Unlike other materials, glass has less tendency to deform under pressure. An ideally flat surface like borosilicate glass stays flat after every print job.

• Alternative materials other than borosilicate glass are used for one print only. The resulting heat and chemicals cause capillary cracks and the tables filled with dirt become unusable. Borosilicate glass, on the other hand, is resistant to 300°C heat, steam and chemicals, and does not deform or expand thanks to its hard surface.

• Borosilicate glass has ideal surface adhesion for 3D printing, as it holds the item steady during the project and releases it easily when the project is complete. Removal of finished parts is very safe and easy, as it has a low coefficient of thermal expansion.

• It is very easy to clean. Particles, sticky and dirty substances on the glass surface are easily cleaned without causing surface deterioration as in alternative trays.